Welcome To Voman Industries Private Limited

your trusted partner for precision engineering solutions.At Voman Industries, we specialize in delivering high-accuracy components and comprehensive manufacturing services.

Welcome to Voman Industries Private Limited – your trusted partner for precision engineering solutions. At Voman Industries, we specialize in delivering high-accuracy components and comprehensive manufacturing services tailored to meet the needs of diverse industries, including aerospace, medical instruments, oil & gas, automotive, and electronics. With a focus on cutting-edge CAD design & modeling and advanced CAM programming for VMC, VMC 4+1 Axis, and turning machines, we are committed to bringing unparalleled quality and precision to every project. From conceptual design to final inspection and small assembly processes, we cover all aspects of the manufacturing cycle to ensure excellence in every component we produce.

At Voman Industries, precision and quality are at the heart of everything we do. We partner with clients to innovate and push the boundaries of what’s possible, delivering solutions that set industry standards.

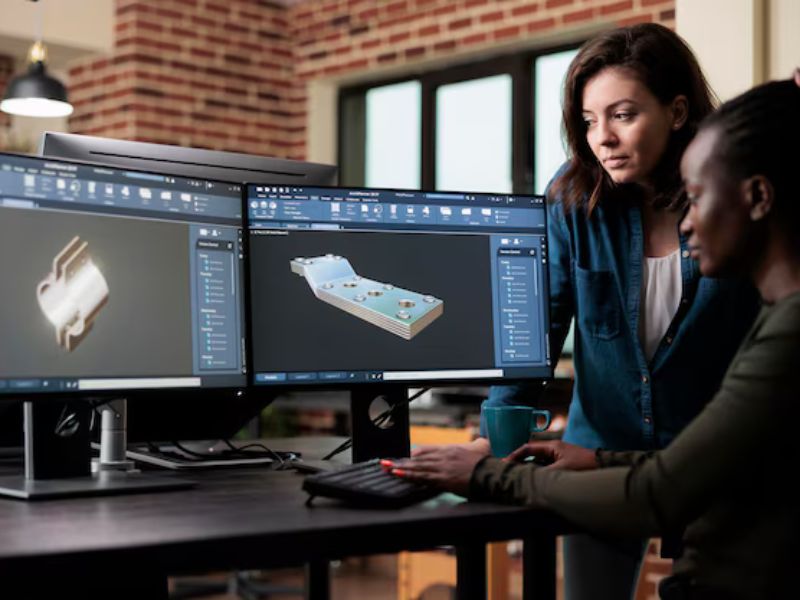

Our expert team of designers utilizes the latest CAD software to create innovative designs .

Our advanced CAM programming techniques for VMC, VMC 4+1 Axis, and turning machines.

Our commitment to quality is backed by a rigorous inspection process.

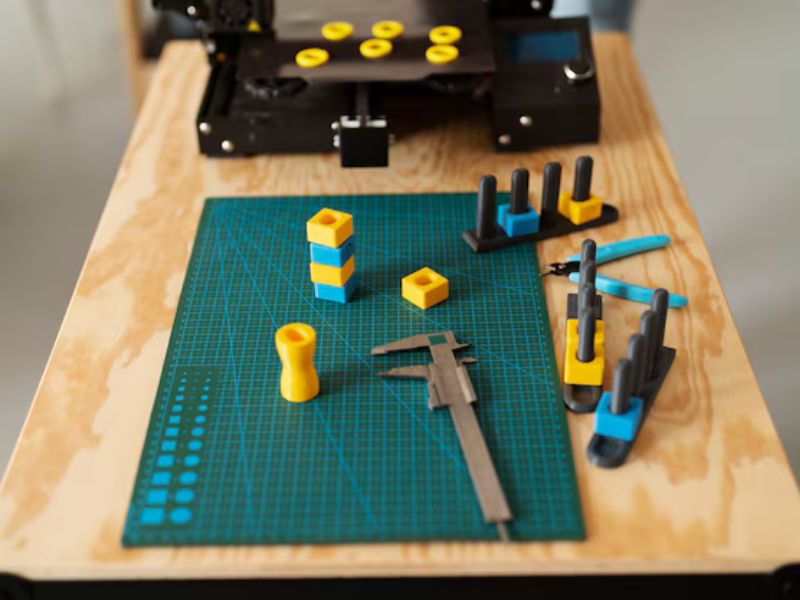

We offer small assembly services to complement our manufacturing process.

At Voman Industries, our mission is to drive innovation in precision engineering. We are dedicated to delivering high-quality components and comprehensive manufacturing solutions that meet and exceed industry standards. Through a commitment to advanced technology and continual process improvement, we aim to support our clients' success by providing reliable, precision-engineered components that perform to perfection.

Our vision is to become a leader in precision manufacturing, recognized globally for our quality, reliability, and technical expertise. We aim to set new standards in the industry by fostering a culture of excellence and innovation, expanding our capabilities to meet the evolving needs of our clients, and contributing to advancements in technology and engineering solutions.

At Voman Industries, our team is composed of skilled engineers, designers, and technicians, all united in a commitment to precision and quality. With our expertise and a customer-centric approach, we aim to be your preferred partner for all precision engineering needs.

Ensuring every component meets exacting standards through rigorous processes and the highest quality control.

Continually investing in technology and skills to drive new solutions in manufacturing and design.

A relentless dedication to serving our clients with transparency, integrity, and efficiency.

Striving for perfection in every service, component, and assembly we deliver.

At Voman Industries Private Limited, quality assurance is the cornerstone of our operations. We adhere to strict quality control measures and a comprehensive inspection process, ensuring each component and assembly meets our high standards before leaving our facility.

Each design is thoroughly evaluated to ensure feasibility and precision before moving into production.

Quality checks are performed at every stage of the manufacturing process to maintain consistency and accuracy.

Every component undergoes a rigorous final inspection to ensure it meets client specifications and industry standards.

No. A275, 6th Main, Peenya 2nd Stage, Industrial Area, Bengaluru - 560 058

info@vomanindustries.in

Reach out to the most reliable manufacturing services.